|

|

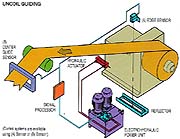

Fife uncoiler systems allow the strip to be continuously

payed off to a predetermined point, utilizing either edge

guide or center guide sensors. The wide-gap reflex

edge sensor (A) shown here is designed to be located

adjacent to the uncoiler, providing stable, accurate

edge guiding results. An alternate solution to uncoil

guiding might be the installation of a narrow-gap,

wide-band, center guide sensor (B) downstream of the

pinch roll/flattener and a control algorithm which

compensates for the phase lag in such a system.

Fife uncoiler systems allow the strip to be continuously

payed off to a predetermined point, utilizing either edge

guide or center guide sensors. The wide-gap reflex

edge sensor (A) shown here is designed to be located

adjacent to the uncoiler, providing stable, accurate

edge guiding results. An alternate solution to uncoil

guiding might be the installation of a narrow-gap,

wide-band, center guide sensor (B) downstream of the

pinch roll/flattener and a control algorithm which

compensates for the phase lag in such a system.

|

|

Features designed into Fife heavy-duty

electrohydraulic power units resulted from an

extensive "needs" study conducted among steel mill

engineers responsible for specifying and maintaining

strip guiding equipment. As a result, these power units

are rugged, reliable, and responsive, providing

simplicity of design, operation, and maintenance. They

employ modular motor-pump assemblies for ease and

speed of maintenance, pump replacement, etc. With

optional standby power, they can operate with one

motor -pump module running while the other is being

serviced. Internal check valves automatically isolate

the active and inactive modules.

Features designed into Fife heavy-duty

electrohydraulic power units resulted from an

extensive "needs" study conducted among steel mill

engineers responsible for specifying and maintaining

strip guiding equipment. As a result, these power units

are rugged, reliable, and responsive, providing

simplicity of design, operation, and maintenance. They

employ modular motor-pump assemblies for ease and

speed of maintenance, pump replacement, etc. With

optional standby power, they can operate with one

motor -pump module running while the other is being

serviced. Internal check valves automatically isolate

the active and inactive modules.

|

|

1. Vertically mounted pumping module eliminates pump-coupling-motor

alignment problems. Complete power module is easily removed with portable

hoist. An optional standby module functions independently to assure continuous

operation during parts replacement or routine maintenance.

2. Submerged hydraulic pump increases life, reduces noise level, and eliminates internal damage from cavitation encountered with exposed pumps.

3. Pressure-compensated, variable volume, piston-type hydraulic pump

runs "unloaded"

except on demand, greatly reducing power consumption, and

providing maximum pump life.

4. Proportional electronically actuated, two-stage, spool-type servo

valve provides optimum accuracy, reliability, and efficiency, Can be furnished

with multiple servo valves for alternate control of multiple coilers.

5. Submerged piping and subplate porting eliminate most external piping

6. Compatible with phosphate ester fluid and other fire-resistant fluids

7. Auxiliary hydraulic ports for optional double-stub traversing or sensor positioning

circuits

|

- For gaps up to 10 feet (3m)

- ldeal for highly reflective strips

- Pulsed LED unaffected by ambient light

- Fully proportional

- Regulated lamp voltage power supply for improved accuracy

- Rugged dust-tight and oil-tight enclosure

- Compatible with "seek" and "stagger wind" features

- Simple to set up

- Rugged positioner optional-sensor manually or hydraulically positioned

- Optional strip width indicator

- SE-20 Sensor may also be used for recoiler guiding

|

|

This package is an integrated hydraulic circuit consisting of

subplate-mounted, electrically operated valves.

The solenoids are prewired to a terminal box, and the

hydraulic connection can be made easily at the side of the

manifold block.

This system is used where it is desirable to operate two

stubs or cone mandrels simultaneously or independently.

It may be used with or without a guiding circuit.

In seeking dynamic equilibrium, a strip will tend to track

perpendicularly to an oncoming roll and is subject to factors

of rigidity, stress distribution, inertia, friction, and load

distribution. These and other factors cause uneven stress and "offtracking" that create

expensive problems. The solution is the proper selection and application of Fife

intermediate guiding systems. Control systems are available for both edge guiding and

center guiding requirements. Most intermediate guides are furnished with a center guide

sensor-making adjustments for strip width changes unnecessary and eliminating the need

for operator attention.

This package is an integrated hydraulic circuit consisting of

subplate-mounted, electrically operated valves.

The solenoids are prewired to a terminal box, and the

hydraulic connection can be made easily at the side of the

manifold block.

This system is used where it is desirable to operate two

stubs or cone mandrels simultaneously or independently.

It may be used with or without a guiding circuit.

In seeking dynamic equilibrium, a strip will tend to track

perpendicularly to an oncoming roll and is subject to factors

of rigidity, stress distribution, inertia, friction, and load

distribution. These and other factors cause uneven stress and "offtracking" that create

expensive problems. The solution is the proper selection and application of Fife

intermediate guiding systems. Control systems are available for both edge guiding and

center guiding requirements. Most intermediate guides are furnished with a center guide

sensor-making adjustments for strip width changes unnecessary and eliminating the need

for operator attention. |